General Capabilities

General Capabilities

Industry demand for single-use components has increased and so has lead times and expenses for these specialized solutions. With fast, flexible, and efficient manufacturing skills, WHK BioSystems can meet your single-use demands with cost-effective, time-sensitive results.

Download our General Capabilities informational sheet today!

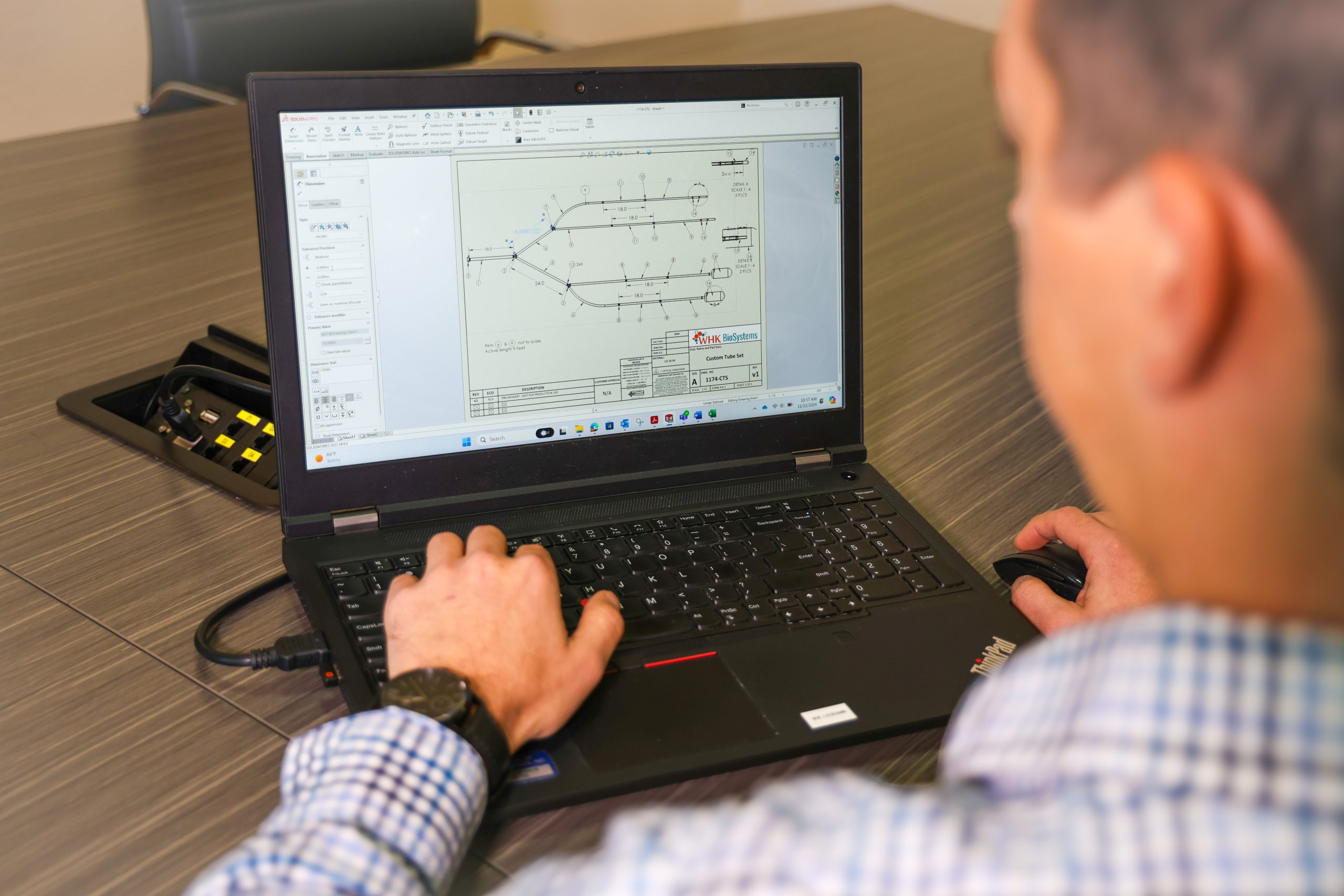

Design Services

From design concept to full-scale production, allow us to partner with you to create the ideal solution for your project. Experienced staff and hi-tech labs allow us to design products without losing sight of cost, quality, or delivery. Learn more.

- Medical Device Contract Manufacturing

- In-house laboratory to conduct rapid testing

- Custom injection molding

- Tooling design and validation

- Regulatory body knowledge and industry experience

Cleanroom Manufacturing

Specializing in products designed for the life science and medical device industries. Certified cleanroom includes injection molding, extrusions, and device assembly capabilities. Learn more.

- ISO 13485:2016 registered quality management system

- Operate Class 7 (class 10,000) cleanroom manufacturing

- Comprehensive quality control systems

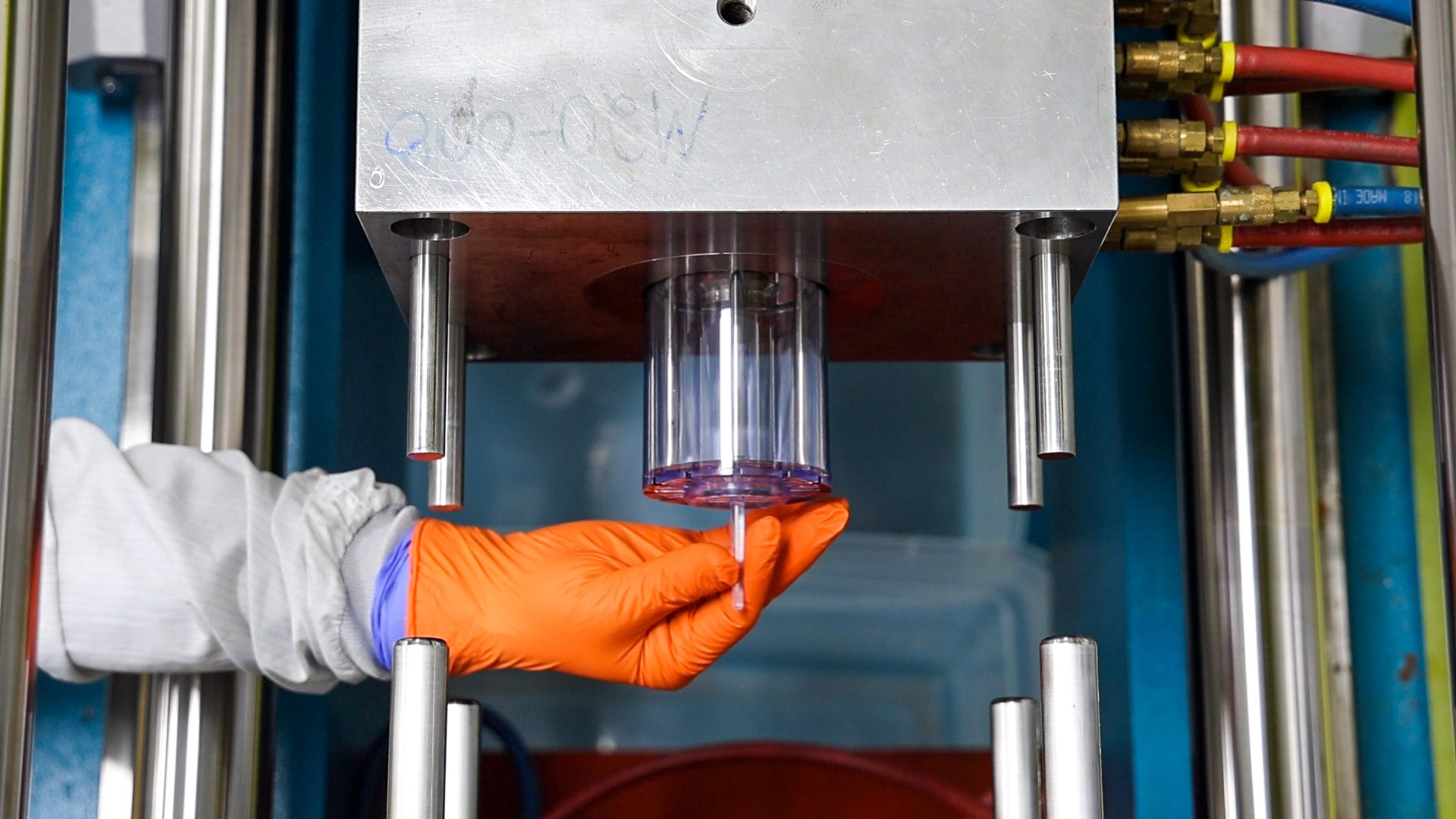

Injection Molding

WHK is continually investing in molding capabilities to ensure we evolve with the needs of the bioprocessing industry. By maintaining our own in-house design and tooling capabilities, we are able to dramatically reduce the production time of medical components and single-use systems. Learn more.

- Specializing in TPE and silicone materials.

- Our diverse injection press sizing allows for full production scalability

- Experienced engineering team with material and processing expertise can handle even the most demanding project requirement

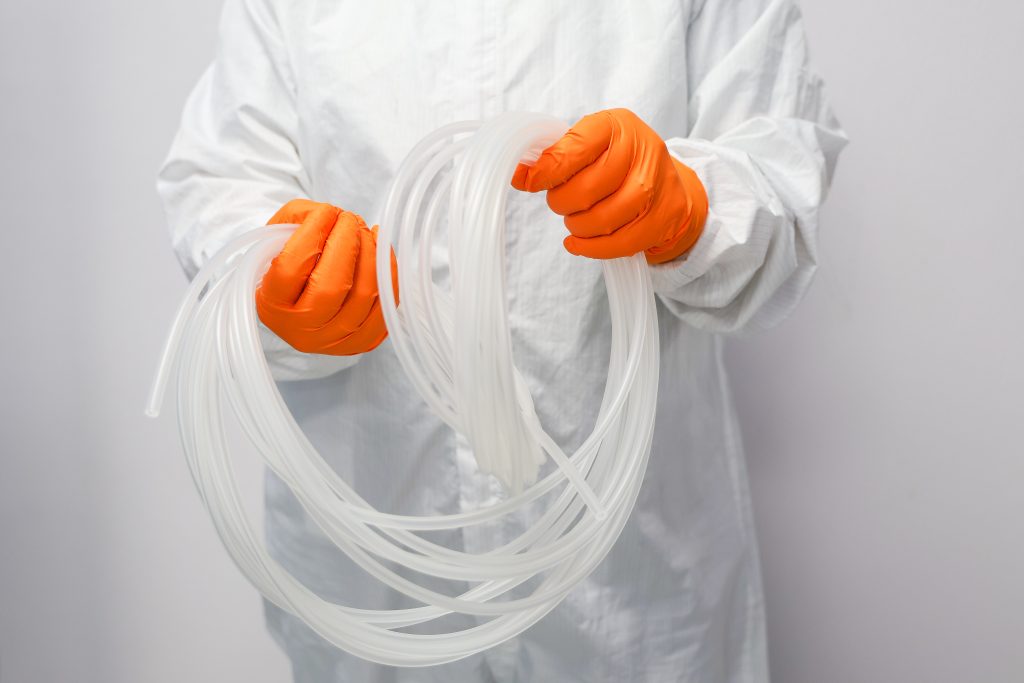

Medical Tubing Extrusion

We have advanced extrusion technology specifically designed to accommodate a variety of applications ranging from biotechnology to catheter tubing. Learn more.

- A broad range of material option (TPE, PP, FEP, PVC, PE)

- BPA, Latex, and Phthalate-free material options

- Laser and ultrasonic measurement systems for precise dimensional control

- Custom printing and packaging available

Learn more about our Custom Tube Kits and W-TPE™ Tubing capabilities.

Complementary Manufacturing Services

WHK BioSystems offers a full suite of fabrication capabilities to complete every project with innovation and quality.

RF Welding Technology

Film welding technology is ideal for low and high-volume production of products ranging from low-pressure bags, barrier sleeves, and sheaths. Film materials include PET, PETG, PVC, TPU film.

Plastic Machining

We offer 3D designs with CNC, lathe, routing, and milling capabilities using a wide variety of FDA approved plastic materials.

Medical Grade Adhesive Application

We provide precise medical-grade adhesive applications, ensuring durable, biocompatible bonds for medical devices and tools.

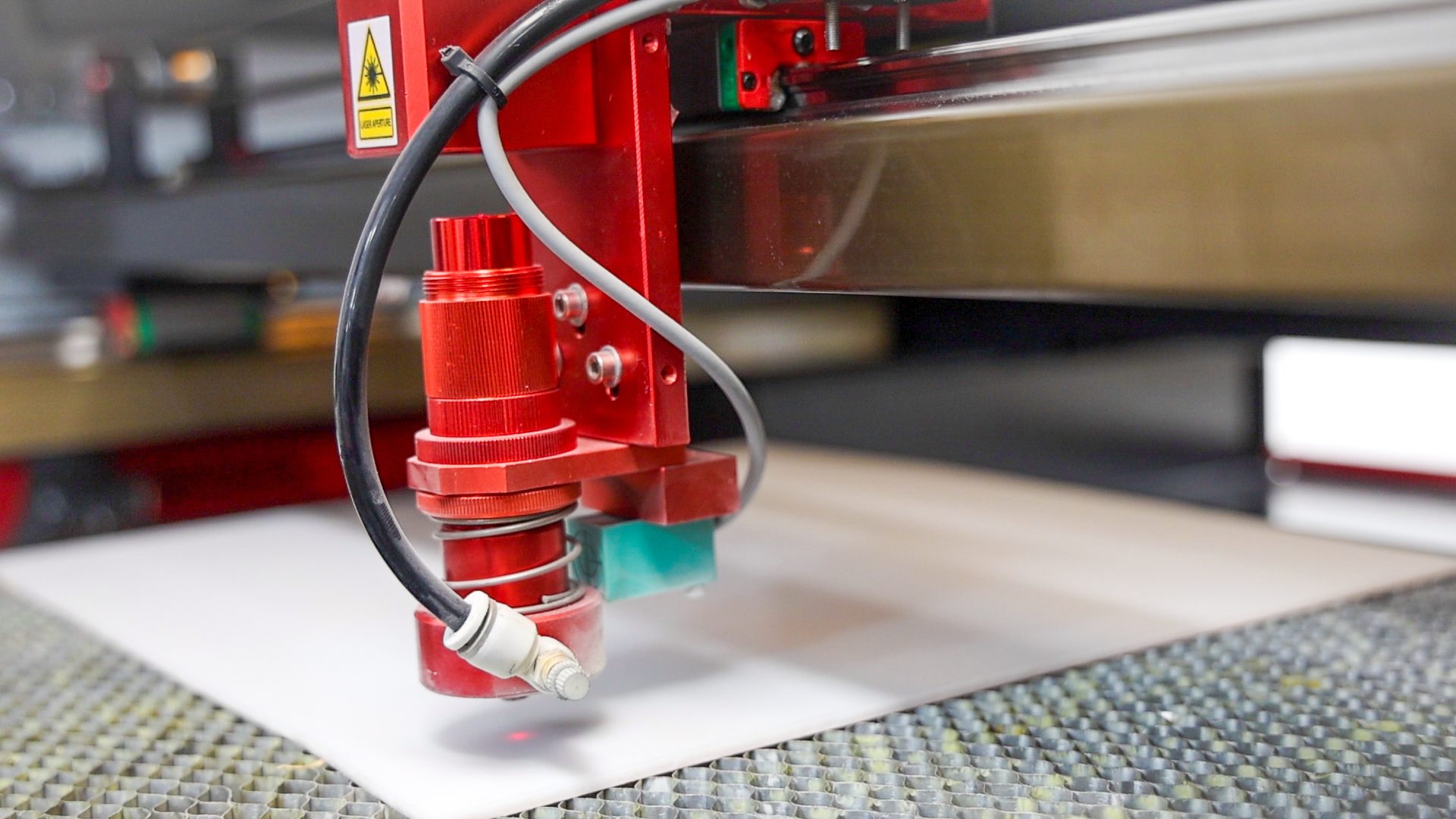

Laser Cutting/Engraving

We utilize a laser system to help us achieve a high level of precision for custom components. With engraving, common applications include serial, lot, or part numbers.

Disclaimer: User is responsible for determining suitability and safety of all products for intended use. Information as supplied on this site is intended to provide guidance only. WHK BioSystems disclaims all liability regarding product fitness for use. WHK BioSystems has also relied on raw material suppliers for a portion of the information and compliance statements contained on this site.

WHK BioSystems, LLC, maintains an ISO 13485:2016 registered quality management system. It operates Class 7 cleanroom manufacturing facilities.